31.10.17 - How One Spadina increased its sustainability with a little help from recycled Canadiana

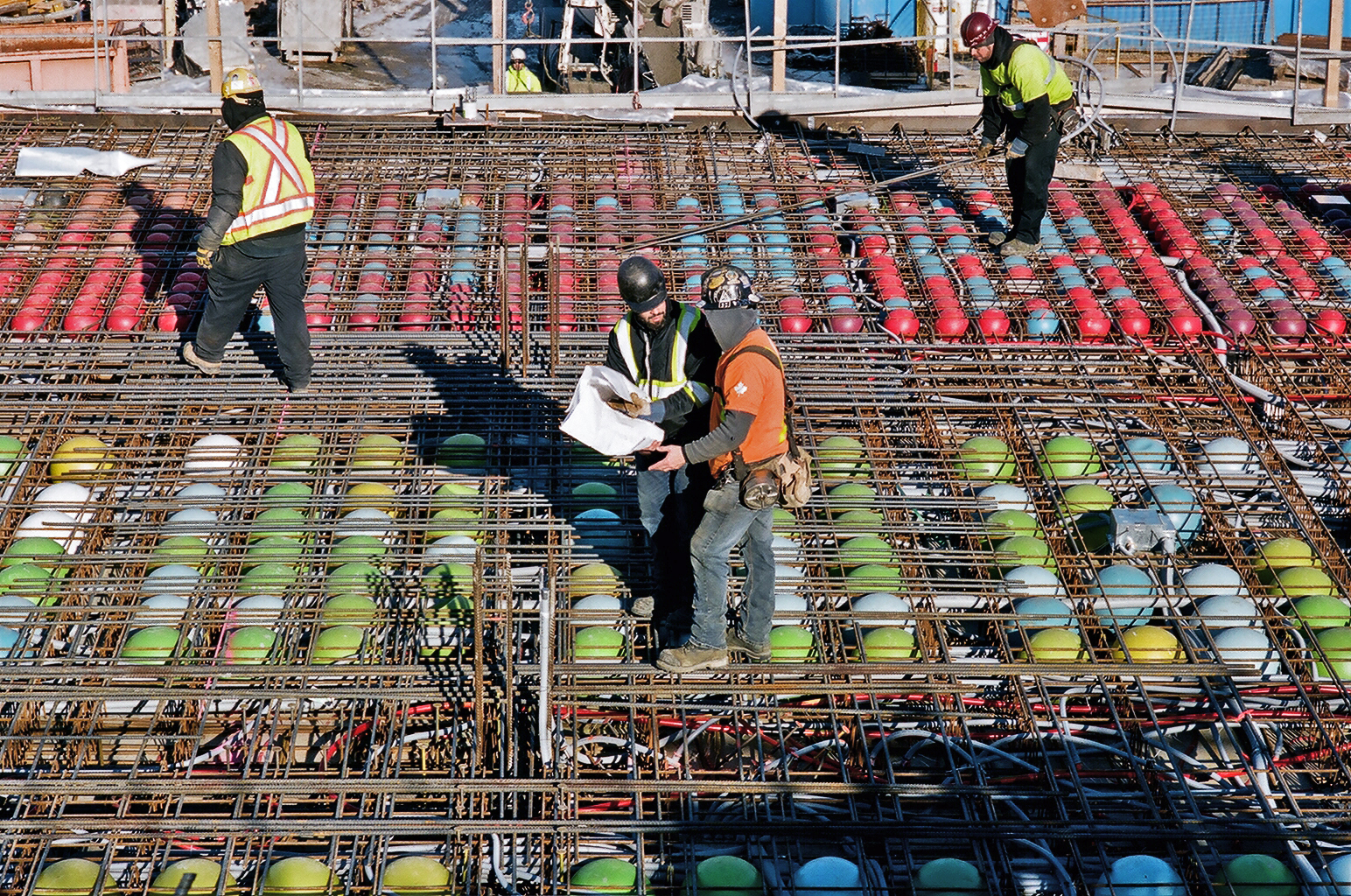

The Daniels Building at One Spadina is now bustling with hundreds of architecture, art, landscape architecture, and urban design students, but many may be unaware that the building's contemporary addition was constructed with some help from an unusual building material: recycled kayaks. The repurposed kayaks make up the “bubbles” in One Spadina's bubbledeck floors — an innovative structural detail that incorporates spherical voids (i.e. bubbles) into what would otherwise be a solid concrete slab.

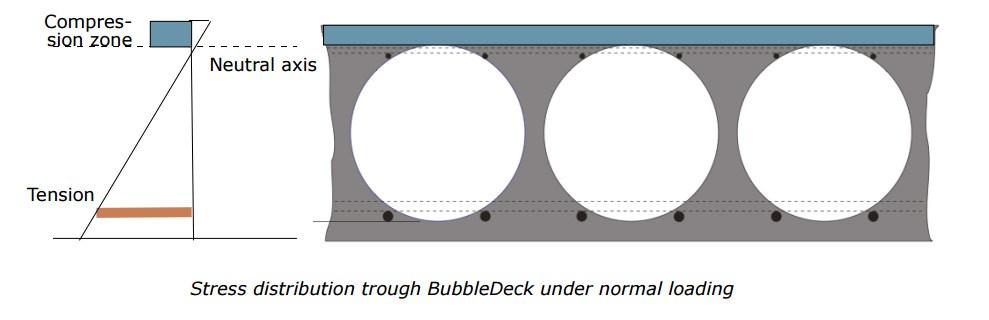

A traditional concrete floor slab is made up of concrete poured into a solid form with steel reinforcements (called rebar) laid throughout. The thickness can vary depending on the type of occupancy, the span in between beams, and a variety of other factors. However, because of the nature of forces moving through a floor, it is actually unnecessary for it to be solid concrete.

Building a solid concrete floor is a simple and well-known practice, but it can result in an excessively heavy floor. As Tom Beresford, Project Manager at NADAAA explains on the firm's blog, introducing spherical voids (i.e. "bubbles") reduces the concrete’s weight while maintaining its structural integrity, which allows the floor slab to achieve longer spans. The bubbledeck slab performs like several “I-beams” stitched together: the concrete mass is concentrated at top and bottom of the section, where compressive and tensile bending stresses are greatest and where they are most needed.

Writes Beresford, "Voided slab’s longer, beam-less spans, combined with its smooth ceiling finish, allowed the [One Spadina] design team to transform spaces that would have otherwise been cluttered with concrete beams and drop panels into clean architectural volumes."

Bubbledeck systems allow designers and builders to produce and use less concrete and more recycled materials, lowering energy consumption and carbon emissions.

But why kayaks?

When we told visitors during Doors Open in May about the bubble deck beneath their feet, they were curious: Why were old plastic kayaks were used? Was there something special about their material? Was there a large recall in the recent past? How many kayaks are people discarding these days, anyway? We asked Jerry Clarke-Ames at BubbleDeck North America for answers.

He explained that the bubbledecks used at One Spadina come from Metelix Products Inc, based out of Brampton, Ontario. Metelix manufactures molded products with High Density Polyethylene (HDPE) which is used to create kayaks. Occasionally, a kayak will be rejected by quality control, and this rejected kayak will be regrinded and saved to make the "bubbles."

"There is no reason to specifically use kayaks," he says. "It's a matter of coincidence."

Fun fact: One recycled kayak can produced fourty bubbles.

Visit NADAAA’s blog for a full description on the construction process and materials used in the bubbledeck slabs.

Photos by Peter MacCallum; Images courtesy of NADAAA.